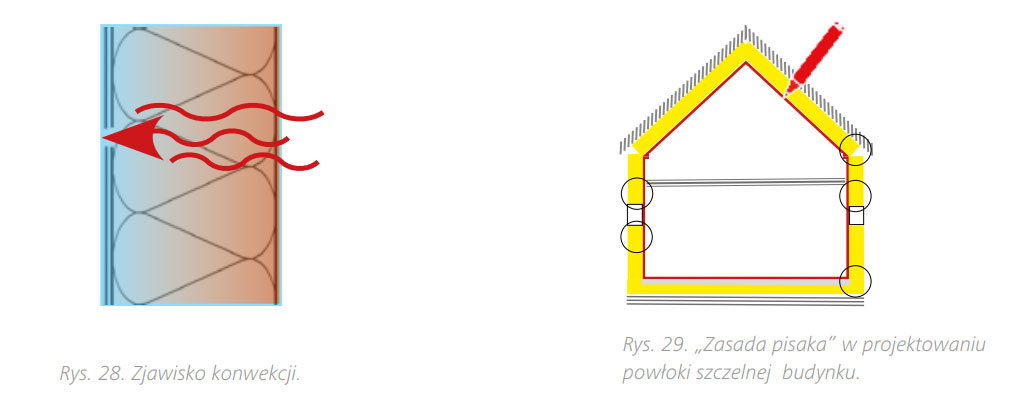

Designing and proper execution of the building sealing layer is one of the most important aspects of sustainable and effective construction in an energy-saving standard. Only a sealed building, in combination with a properly selected thermal insulation layer, is able to provide the required thermal comfort. Regardless of the type of object, the air-sealing layer is assigned on the inside of the building partition. In certain cases, it is also possible to make a sealing layer located on the outside of the partition. The task of the sealing layer is to protect the building partition against the so-called convectional air exchange. The phenomenon of convection is one of the natural methods of leveling the water vapor pressure difference (apart from the process of moisture diffusion). Convection works effectively only in continuous gaps of building elements (leakages in the sealing and wind insulation layer – drawing no. 28). The lack of resistance leads in such a gap to an intensive, fast exchange of air – together with the air it is discharged from the room, for example moisture. Because during this process the air cools down very quickly, the risk of local formation of condensate is very high. The condensation of water vapor inside the barrier occurs when the warm and humid air coming from inside the room cools down during penetration into the cooler air outside the building. Cooled air quickly reaches the so-called dew point temperature at which the air has the highest relative humidity of 100%. Cold air can take a much smaller amount of water vapor than warm air, resulting in a further cooling of the air during migration inside the barrier causes that excessive amount of moisture condenses in the form of condensate settling on the cold surfaces of building partitions. In view of the above, every effort should be made – from the design process to the implementation itself – to ensure air tightness of all building partitions. Air tightness of the building also affects the microclimate of the rooms. In the winter season, in the case of insufficient tightness, cold air, entering the building, is heated. In this way, the relative humidity in the room decreases. Relative humidity of the air in the winter season below 40% causes discomfort to users, for example is the form of drying of the conjunctiva. In the summer season, the air-tightness of the building ensures the possibility of achieving a phase shift, referring to the time in which the heat resulting from solar radiation reaches the interior of the building through the partition, thanks to which the rooms do not undergo immediate heating.

In the construction of a light wooden framework open to the diffusion of water vapor, air tightness can be obtained by using materials fastened directly to the structural elements: – vapor barriers, – wood-based panels (eg OSB) sealed at joints, – drywall approved, sealed at connection points. Important: The layers ensuring tightness are not always a barrier to the phenomenon of moisture diffusion. Building barriers should also be protected against free inflow of air from the outside to the inside. For this purpose, on the external side of open diffusion frame structures, a windproof coating is used in the form of: – hydrophobized, multifunctional wood fiber boards with tongue and groove (for ventilated facades and as a rafter insulation), – multifunctional wood fiber boards with a feather profile groove (for approved plastering systems), – highly vapor permeable membranes.

The ordinance of the Minister of Infrastructure on the technical conditions that should be met by buildings and their location recommends the design and construction of partitions, connections between partitions and partitions, as well as the passage of installation elements and connection of windows with reveals in order to achieve total air leakage. The sealing layers of individual building elements should be tightly connected, so that they eventually form a uniform, uninterrupted coating. A properly designed building sealed coating should be able to be traced along the inner volume without “tearing” the pen from the paper (Fig. 29). The air-tight coating, which will be relatively easy and safe to make during construction, can be achieved by following the following recommendations: – all details should be designed in a way that guarantees the simplest, low-invasive design (ensuring limited penetration of the coating); – design as large and closed surfaces as possible based on systemic, tested solutions; – all sealing materials should constitute a uniform, mutually fitting system of proven quality and with a manufacturer’s guarantee. Practice confirms that even the smallest penetrations of the sealing layer (mainly vapor barrier membrane) or inaccurate connection between sealing materials cause progressive, serious construction damage. Leaks in the internal surface of the building envelope cause, among others, uncontrolled convectional penetration of warm and humid air into the partition through gaps, joints, contacts. This leads to the inter-layer condensation of water vapor, which results in a progressive deterioration of thermal, acoustic and durability of the barrier. Heat losses affect the energy performance of the building, and thus the higher heating costs. Research carried out by the Institute of Building Physics in Stuttgart indicates that already a 1 mm gap and 1 m in length, under certain thermal conditions, causes a deterioration of thermal insulation by 4.8 times in relation to the tight building partition. The moisture level of such a barrier increases 1600 times in relation to the partition subjected to the natural process of water vapor diffusion. To avoid building damage as a result of the leaky internal coating of the building, it is recommended to check it before putting the building into use.