Fire resistance (REI) is characterized by the ability of a building element to meet certain utility functions for a specified period of time in fire conditions. The individual functions (load capacity – R, tightness E, insulation – I) are marked with symbols, whereas the time intervals within which criterion/criteria are met are determined numerically (30, 45, 60, 90, 120). According to popular opinion, wooden structures are characterized by very low fire resistance. This view is very misleading, as evidenced by numerous flammability tests carried out in laboratories dedicated to fire tests and the state of preservation of existing objects exposed to fire. It will not be a mistake or an exaggeration to say that system wooden structures belong to one of the best researched and the safest in the world in terms of fire protection according to the current state of knowledge.

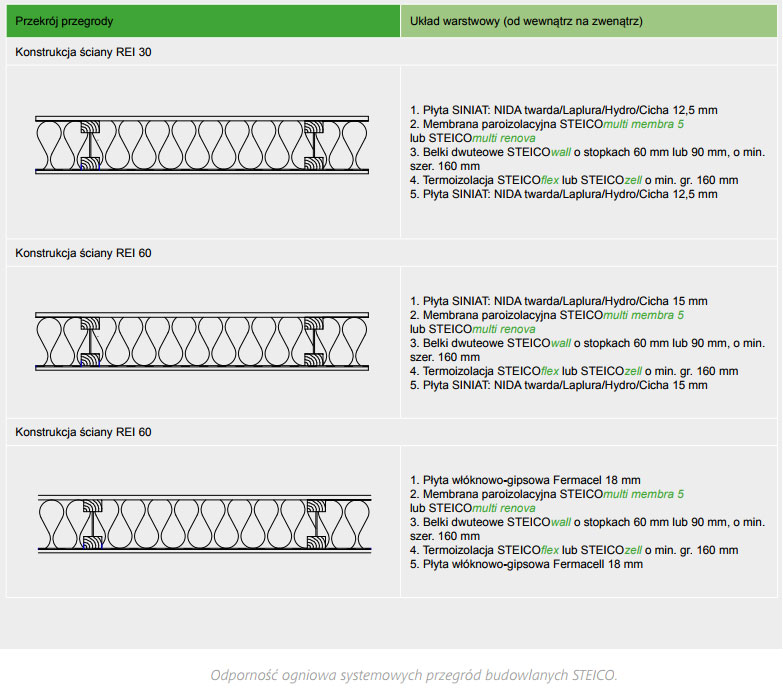

Contrary to popular opinion, the most common reasons for the occurrence of fires are not the properties or fire classification of the materials that make up building partitions, but the usual carelessness, incorrect use of electrical equipment and installations, as well as their factory defects. Unfortunately, these are factors that cannot be eliminated by simply shaping the appropriate layered barrier system. A properly designed, constructed and used building creates a small risk of automatic emergence and scattering of fire. The statistics show that most fires are initiated inside the rooms, therefore the type of furniture, decorations and finishing materials is of particular importance in the context of the possibility of spreading fire. It is also important to choose a suitable finishing board, which in the event of a fire will protect the structure of the building partition. In modern wooden constructions, the basic internal lining is commonly known plasterboard, gypsum-fiber boards or special fire-resistant plasterboard reinforced with fiberglass. Their application, depending on the thickness and number of layers, significantly increases the fire resistance of frameworks. Gypsum contains a significant amount of water, which under the influence of increasing temperature evaporates. This process absorbs a significant amount of heat, thanks to which the interior of the partition is protected against a rapid increase in temperature. During this time, the mechanical strength of the panel is significantly reduced, additionally its shrinkage is observed, the value of which can reach up to 10%. Therefore, it is important to properly attach the plate to the frame. The engineering practice has proved that in order to fully use the protection that is obtained with the use of plasterboard, it is necessary to use as little spacing of screws or nails and ensure adequate penetration of the connectors into the skeletal elements. Timber structures thermally insulated with wood fiber materials, in combination with appropriate sheathing panels and finished from the outside with, for example, a layer of plaster, show fire resistance from 30 to 120 minutes – depending on the adopted layer system. The designer’s task is to select the layered structure of building partitions so that they meet the requirements of fire protection in accordance with the applicable construction law.

Fire classification – thermal insulation materials made of wood fibers

Thermal insulation materials STEICO made of wood fibers due to the behavior during a fire are counted in accordance with the applicable standard EN 13 501-1 to Euroclass E, while according to the German standard DIN 4102 to class B2. In both cases, the thermal insulation material of wood fibers is classified as “normally inflammable”. At the same time, it is worth noting that: – thermal insulation materials made of wood fibers in the form of boards do not require the addition of special impregnating agents during production in order to obtain classification E. Appropriate fire resistance is ensured in this case by a relatively high plate density and a characteristic texture of fiberisation; – “lighter” thermal insulation materials made of wood fibers in the form of elastic mats or pellets for blowing (dedicated to fill voids) are additionally protected in case of fire contact. The impregnating substance is an additive in the form of ammonium sulphate. In addition to being used as a natural fire-protecting impregnation in eco-friendly construction, this compound is used, for example, as an additive to foodstuffs. During numerous documented fire resistance tests of wooden partitions using panels, mats and granules of wood fibers, it was found that these materials contribute to a direct improvement of the fire protection of the tested element. The high specific heat c and the relatively high bulk density of the described insulation products significantly delay the penetration of temperature through the building element during a fire, protecting the subsequent layers of the barrier against ignition.