The thermal insulation of the external building partition must be designed in such a way that throughout its entire period of use it creates the necessary conditions to ensure the thermal comfort of its residents. In other words, the building should provide an internal climate in which people do not feel unpleasant cold or heat, even when the external climate conditions do not contribute to this goal.

Layer system of partition in combination with the heating and cooling system should be selected so that the entire outer shell of the building is able to compensate even the largest fluctuations in outdoor air temperature and temperature fluctuations caused by interruptions in the supply of heat or cold from internal systems. Suppression of temperature fluctuations is achieved by ensuring a sufficiently high thermal stability of the building in combination with an optimally low heat transfer coefficient U.

A properly designed and made frame construction system using thermal insulation materials made of wood fibers in combination with load-bearing highly processed wood allows to achieve not only legally required values of heat transfer coefficients U, but also a relatively long phase shift and a favorable suppressing of the amplitude of temperature fluctuations. These values are often overlooked in the energy performance of the building, although they are necessary to be considered in the context of providing a year-round thermal comfort at a high level.

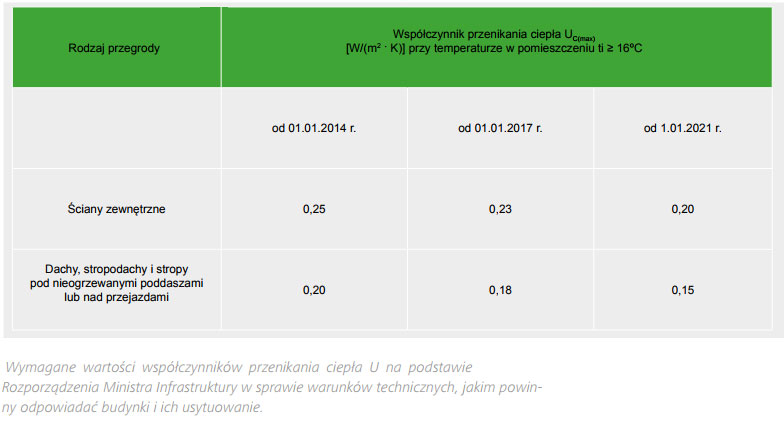

The analysis of the amendment of the regulation allows to state that in the light of the law, the requirements for thermal insulation of buildings will be regularly exacerbated. It results from the accepted legal acts, including Directive 2002/91 / EC of the European Parliament and of the Council of Europe on the energy performance of buildings.

Building structures with significantly lower heat transfer coefficient values, even below 0.08 W / (m2 · K), are already constructed for wall and roof constructions. We are talking about buildings designed and implemented in a low-energy standard or in an increasingly widespread passive standard. Such buildings are characterized by a very low demand for thermal energy obtained through the use of high-quality thermal insulation materials, window and door carpentry or efficient mechanical ventilation systems with heat recovery.

Because of high awareness of the benefits of energy-saving construction, increasing costs of energy needed for heating and cooling buildings, as well as legal regulations obliging to minimize the demand for thermal energy, modern construction in wooden frame technology becomes an extremely optimal solution for the future.

Thermal insulation in summer in practice

In addition to the outer roof covering and the inner shell layer, the roof structure storage mass is based only on the thermal insulation material. Therefore, it is particularly important to adjust the amplitude suppressing and phase shift using an insulating material that has a very low temperature leveling factor a. At an external temperature of 35 ° C, the temperature under the roofing can reach the already mentioned + 80 ° C. Only the application of a well-thought-out layered system will suppress and slow down the flow of such high temperature to the building’s interior.

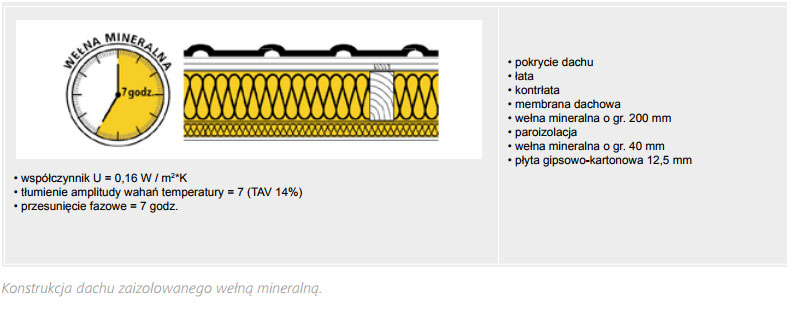

A roof with mineral wool insulation with a thermal conductivity of 0.035 W / (m * K) and with a density of 20 kg / m³ has according to calculations the attenuation of temperature fluctuation amplitude equal to 7 (TAV 14%) and phase shift of seven hours. According to calculations, an increase in temperature to 29 ° C will occur on the inside of the roof barrier at 19.00. However, this temperature is definitely too high in the context of thermal comfort (providing a pleasant sleep). At 19:00 the outside temperature is still at a similar level, therefore airing the rooms does not bring a noticeable relief, and mechanical ventilation requires an increased demand for energy (in order to cool relatively warm outside air).

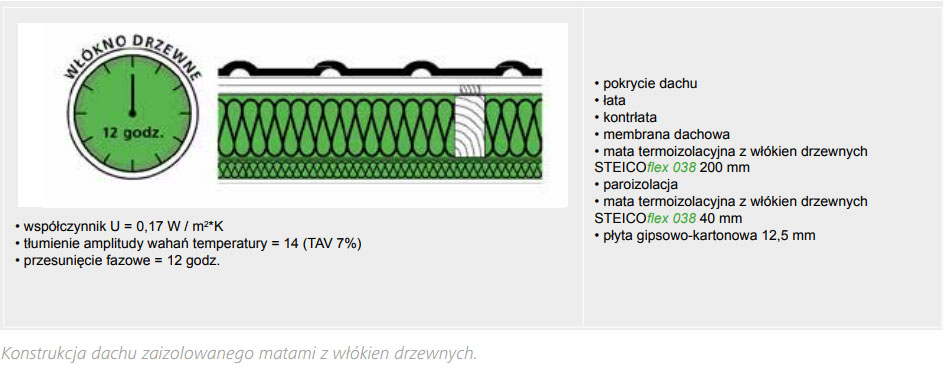

Replacing an identical roof structure with mineral wool for a thermal insulation mat of wood fibers with a thermal conductivity of 0.038 W / (m2 * K) and a density of 50 kg / m³, a five times higher accumulation capacity of the thermal insulation layer will be obtained. The reason for this state is m.in. high specific heat c of wood fiber mats. For a roof partition, this means doubling the attenuation of the temperature fluctuation amplitude to 14 (TAV 7%) and to improve the phase shift by five hours, that is to say up to 12 hours in total. Also, the temperature flow to the room is much better in this case: the temperature on the inside of the roof is raised to a maximum of 21 ° C, and only at 23:00. During this time, the outside temperature is much lower, so if the temperature of 21 ° C is uncomfortable for the users, it can easily be reduced by ventilation (or ventilation) of the room.