RECUPERATION

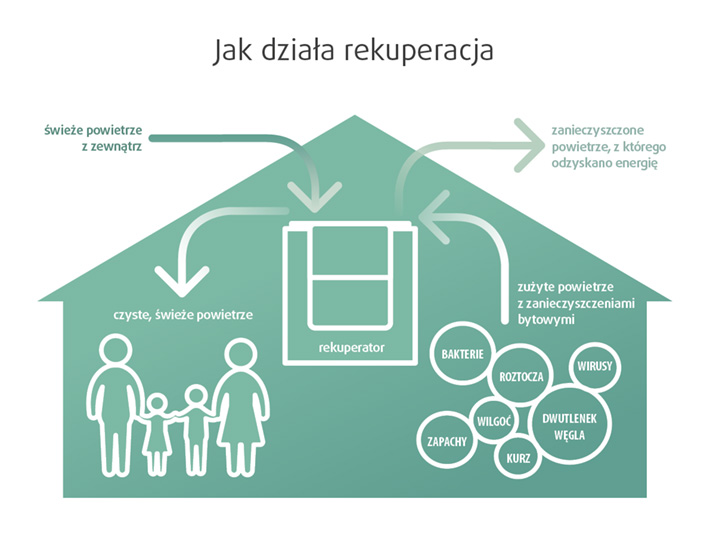

Recuperation – it is a modern system of mechanical ventilation involving the retrieval of heat energy using a heat exchanger. This process takes place in a special ventilation unit (recuperator) equipped with such an exchanger. The principle of ventilation process with heat recovery consists of supplying and heating fresh air into a residential building with used air removed from a building passed through a heat exchanger.

BENEFITS

Replacing the used air: at home with recuperation, you always breathe fresh air.

Filtration of supplied air: effective protection against smog. Mechanical ventilation also gives the possibility of filtration of the supplied air. The level of filtration depends on the class of the used filter. Factory recuperator is equipped with G4 class pocket filters.

The installation of a filter with an increased filtration class F7 (can only be used for ventilation) makes it possible to stop over 90% of suspended dust of 1-10μm and less than 75% of dust with dimensions of 0.3-1μm (smog pollution is mostly PM10 dust, which means that the dust size does not exceed 10μm).

Savings on heating: Once used heat is re-used. Heating bills in the winter months decrease to 50% compared to operating gravity ventilation. This is because the recuperator heat exchanger transfers energy from the extract air to the supply air stream. Thanks to that, the house has a lower demand for primary energy (EP) even by 20 kWh / (m2). This is very much, especially in the light of EU regulations on reducing the energy demand of a house by 2021.

Possibility of installing a ground heat exchanger. Possibility to use energy from the ground: the air to the recuperator goes already pre-developed: cooled in summer and heated in the winter. Also great help for the system during very low or high outdoor temperatures.